Simple, Dependable, Proven Technology for Incredibly Efficient Dehydration of Large Volumes.

An Effective and Enduring Equation... Time + Temperature + Forced Convection = Operational Success and High Profits.

⚙While the technology may not be new, Midwest Custom Solutions will help you design, engineer and build your next forced convection, continuous conveyance Tray Drying System specifically created for your own product’s unique operational requirements and dehydration essentials.

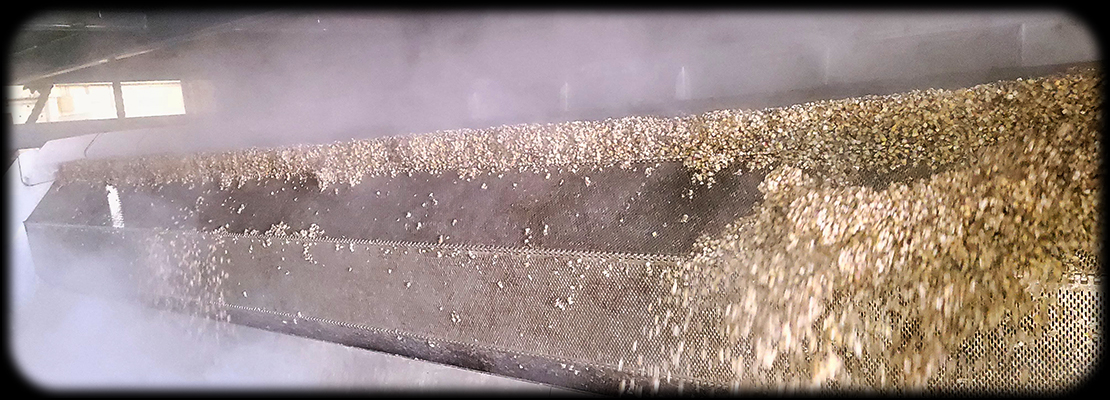

⚙Simply explained, “Forced Convection” consists of large-volumes of controlled, heated air circulated over and through the process material which has a high- moisture content. As the dry, heated air is moving around the material, moisture is drawn out of the product in the form of water vapor or steam. The water-saturated air is then removed from the dryer via a process air exhausting system.

⚙This simple dehydration technique has been utilized for eons, however, when large volumes of valuable product material like yours requires precise, specific results, MCS is here to partner with you in providing a custom solution perfect for your individual critical needs and operational requirements.

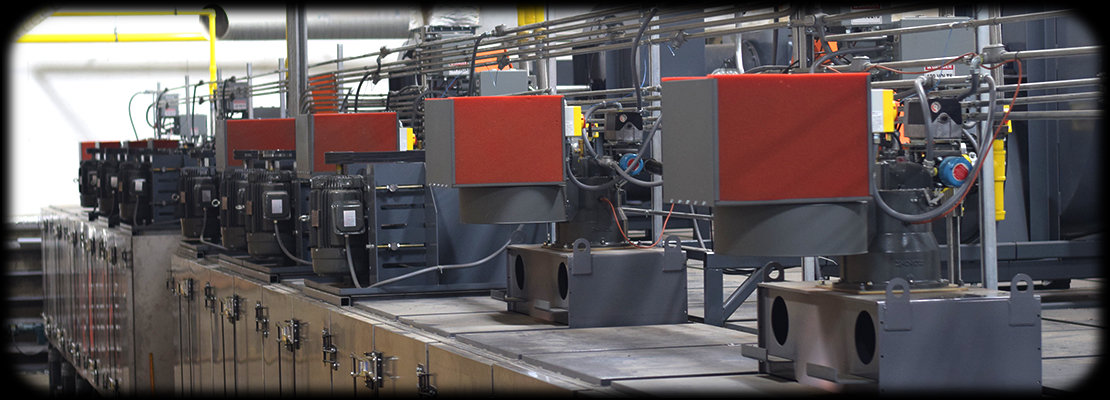

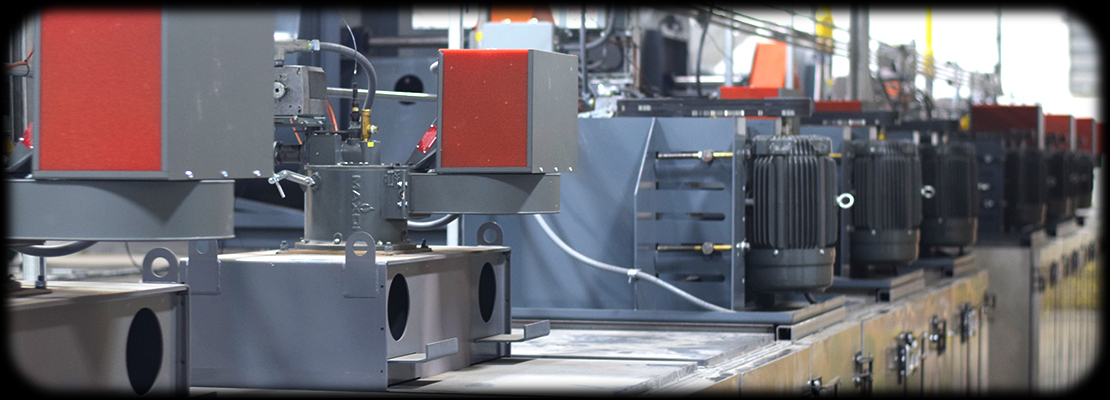

⚙As with all systems and products manufactured by Midwest Custom Solutions, we’ve selected only the highest-quality components and materials for our XT Series Tray Dryers including industry-leading bearings, burners, motors, gearboxes and drive mechanisms for the perforated tray conveyor assembly.

⚙Each frame section of our XT Series Tray Dryer System is constructed of high-quality steel tubing and precision assembled by our highly-skilled fabrication technicians. All welds are meticulously placed with artisan craftsmanship and intent yielding high material penetration which guarantees countless hours and many years of worry-free processing.

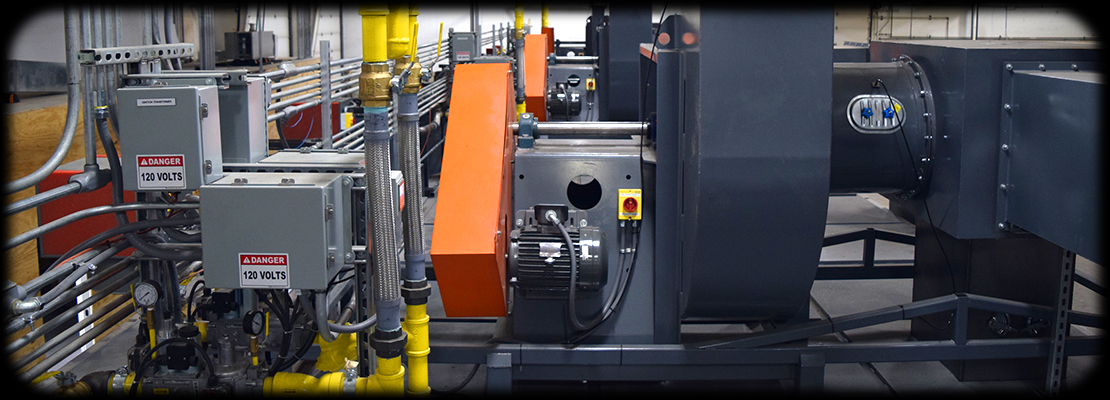

⚙Burner assemblies and Burner Management Systems (BMS) for our XT Series Dryers are only selected from industry-leading manufacturers and suppliers for their high-efficiency operation and extreme durability delivering controlled, precise and extraordinarily-efficient service air to your dehydration operations.