A New Revolution in Pellet Drying and Cooling Innovation has begun...

and we're the ones who started it.

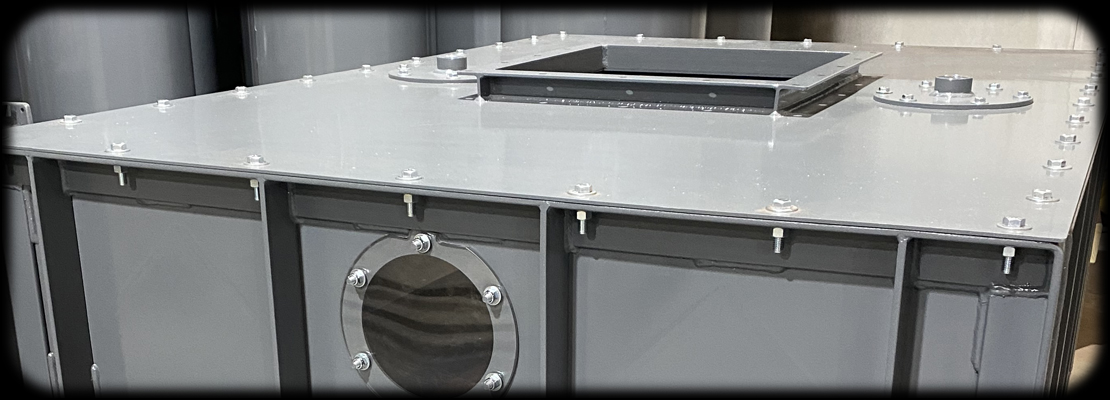

Introducing the most advanced pellet cooling technology available on the market today: The VertiCool XC Series Dryer/Coolers from Midwest Custom Solutions are ready to stand up to your toughest pellet processing challenges with the safest, most efficient design offered in our industry.

Not only do our XC Series Dryer/Coolers have the cutting-edge, reliable, rugged design you've come to expect from MCS, but also provides 50% more throughput of finished product per square foot of floor space than other antiquated pellet coolers which provide outdated, inefficient drying processes.

Perfect Pellets... Every Time. Your Pellets are Our Priority.

We proudly present to you a better way to achieve precision in the art of pelleting.

Your endeavor of achieving perfect pellets every time is closer than you may have imagined.

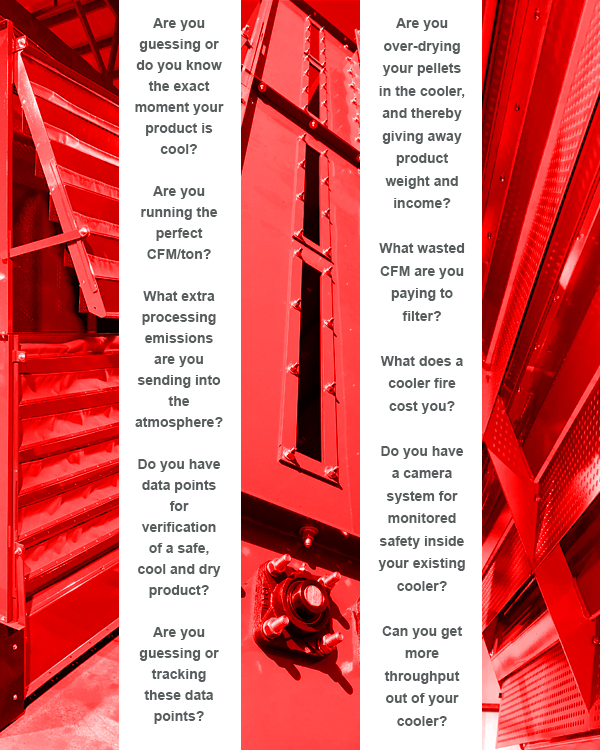

⚙Are you guessing or do you know the exact moment your product is cool?

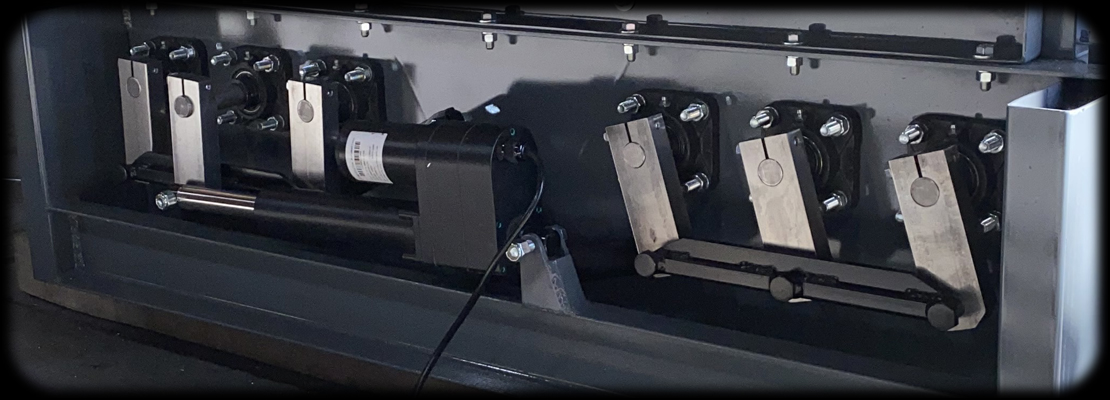

The name of your game is “efficiency,” and we know exactly how to play. The XC Series Dryer/Coolers from Midwest Custom Solutions offer a fully automated control system with complete monitoring of product moisture and temperature levels throughout the pellet cooling process. This means you maximize your product throughput and minimize your process energy consumption to achieve the greatest operational efficiencies possible.

⚙Are you running the perfect CFM/ton?

Incomplete drying and cooling is an integral function of the pellet system ahead of the cooler, but how do you currently know you have a problem? Processing your pellets inefficiently means you’re wasting money consuming time, electrical power and cooling air needlessly. The XC Series design is specifically engineered to utilize the precise amount of CFM to automatically match the product throughput of your equipment. Our sensor system will immediately alert you to conditions which may be addressed before they grow into rejected loads. With our XC Series you'll have precise measurement and control over moisture levels at the cooler.

⚙Are you over-drying your pellets in the cooler, and thereby giving away product weight and income?

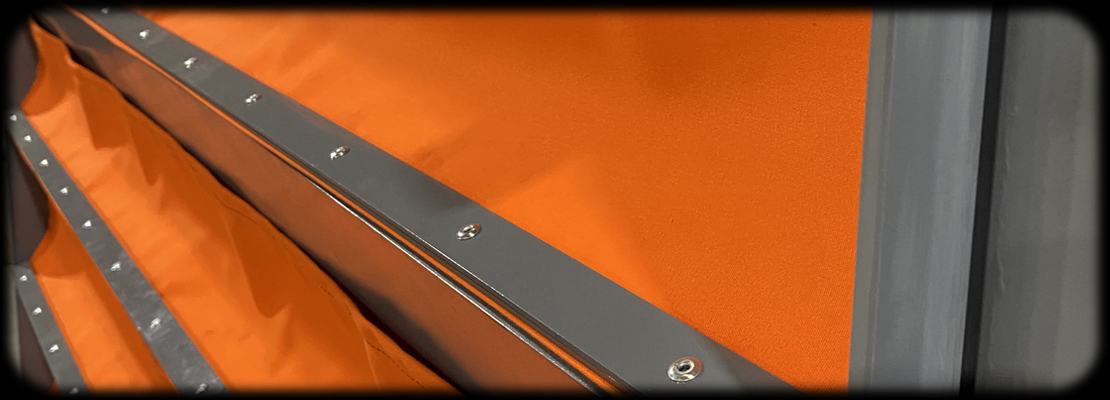

The moisture content of your processed pellets is a delicate balance. The XC Series Dryer/Coolers are explicitly designed to provide precise control over your pellet moisture content and temperature levels, thus eliminating under-processing AND over-processing. Our equipment doesn't use any more air than is necessary to cool your product. Once cooled, processed pellets are discharged automatically.

⚙What wasted CFM are you paying to filter?

The air we breathe is plentiful, but the filtration of your processing air is not. Pinpointing the amount of energy to accomplish your moisture and temperature goals is the only way to win in the battle of efficiencies.

⚙Do you have data points for verification of a safe, cool and dry product? Are you guessing or tracking?

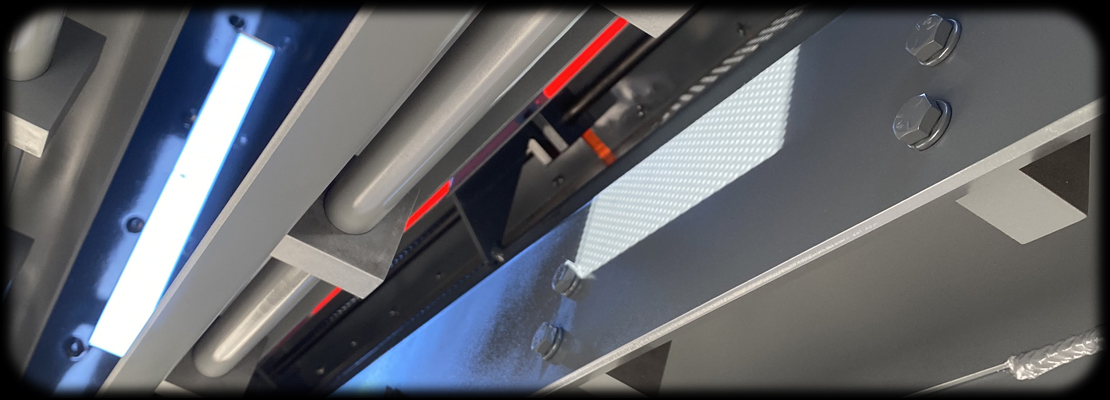

We offer an optional PLC Panel control for our XC Series Dryer/Coolers to ensure your operations are even easier and more precise. Industry-leading temperature and moisture sensors in our design are installed as standard features to eliminate the “guesswork” which is costing you money in inefficient operations.

⚙What extra processing emissions are you sending into the atmosphere?

Emissions play a major role in pellet processing and are a growing concern in all process plants today. Our XC Series Dryer/Coolers stand at the forefront of caring about the air we breathe and the safety of the communities we serve. Applying the equipment’s design efficiencies will allow you to use just the right amount of air to achieve your desired moisture content and temperature levels. Other designs use excess air inefficiently to guess at your desired targets.

⚙What does a cooler fire cost you?

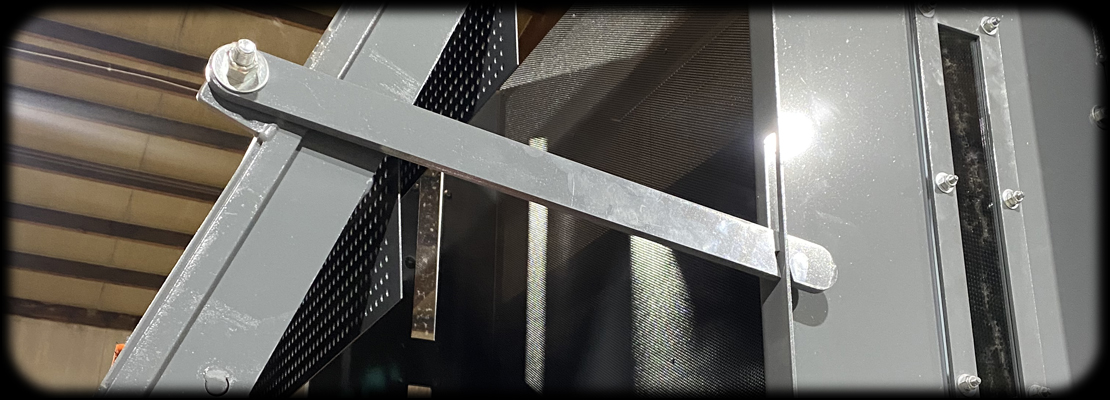

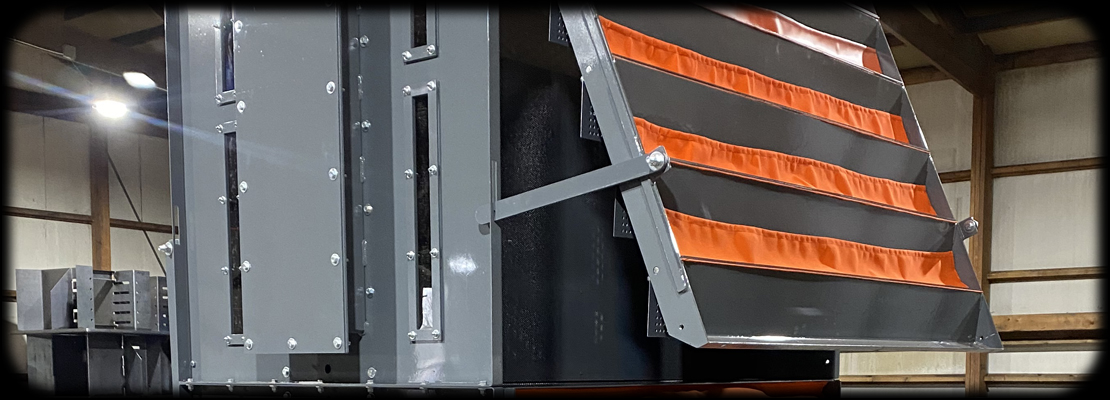

We mitigate and diligently strive to eliminate those concerns. The XC Series technology continuously monitors the temperature level and moisture content to mitigate any fire risks. Hot spots are a thing of the past with the equipment’s advanced detection and fire suppression control. Ease of cleaning has also been engineered into our XC Series product line with hinged louver panels which swing-out providing simple access to critical components for maintenance and debris removal.

⚙Do you have a camera system for monitored safety inside your existing cooler?

Midwest Custom Solutions offers an optional camera installation to ensure automated cleaning is being performed appropriately and thoroughly. Rapid identification of processing residues is quickly provided, and preventative maintenance is easily verified by all in your operations.

⚙Can you get more throughput out of your cooler?

If you’re using antiquated processing techniques, the answer is: “probably not.” We offer five versions of our XC Series Dryer/Coolers to accommodate your unique equipment setup or individual processing requirements. When operational size restrictions present installation concerns, one of the XC options will provide 50% more throughput of finished product while occupying the same footprint.

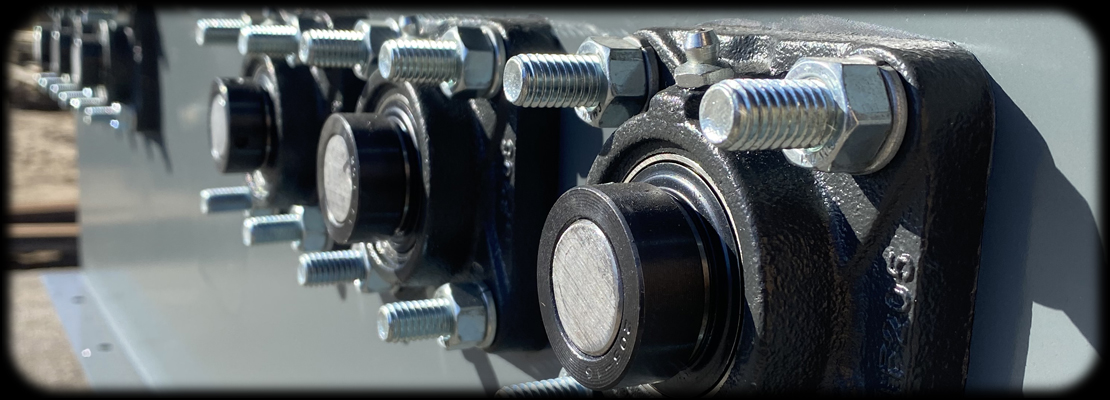

Only high-quality materials are used throughout our products to ensure years of carefree, efficient operation, and we are here to partner with you to help your business grow to the next level.

US / STANDARD

Height (XC1) . . . . . . . . . . . . 92.00in. / 7.67ft.

Height (XC3) . . . . . . . . . . 146.00in. / 12.17ft.

Width . . . . . . . . . . . . . . . . . . 64.25in. / 5.35ft.

Length . . . . . . . . . . . . . . . . . 49.63in. / 4.14ft.

Clearance (Front & Back) . . 17.00in. / 1.42ft.

METRIC

Height (XC1) . . . . . . . . . . . 233.68cm / 2.34m

Height (XC3) . . . . . . . . . . . 370.84cm / 3.71m

Width . . . . . . . . . . . . . . . . . 163.20cm / 1.63m

Length . . . . . . . . . . . . . . . . 126.06cm / 1.26m

Clearance (Front & Back) . . . 43.18cm / .43m

So, you really like what you're seeing, but our XC Series Dryer/Coolers aren't quite what you're looking for?

Let's talk about it.

Feel free to reach-out to us using our Contact page and we will be happy to answer your questions or address your concerns.

We look forward to speaking with you!

Would you like to download the Midwest Custom Solutions' XC Series Dryer/Cooler Product Marketing Brochure?

Click/Tap the "GET PDF" button above to obtain a printable, transportable PDF version of our XC Series product information above.

Copyright © 2023 Midwest Custom Solutions. All Rights Reserved.

Information contained on this site is presented for marketing and reference purposes only.

WARNING: DO NOT design, plan or engineer ANYTHING based solely on the reference material contained within the MCS website.

Speak with our Sales and Technical team for engineering specifics of MCS products and equipment by clicking the following: Contact

Be sure to review the MCS website legal pages: Terms of Use ❙ Privacy Policy ❙ Cookie Policy ❙ GDPR