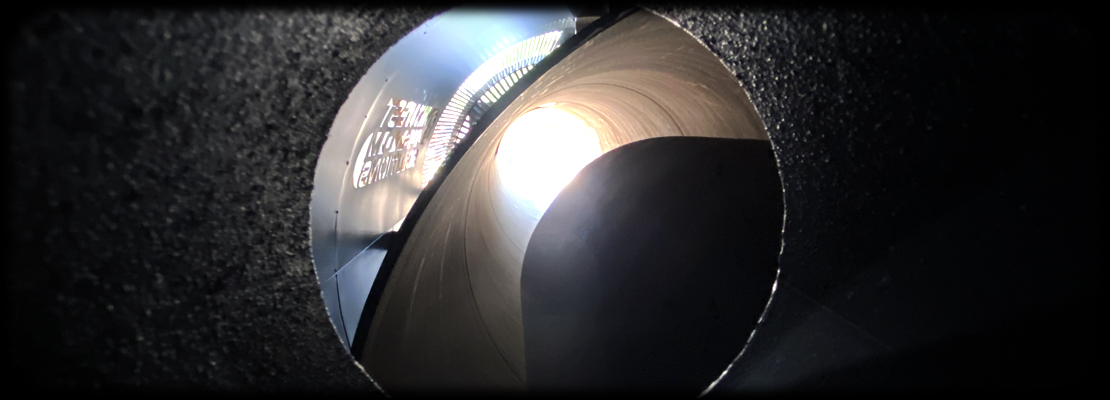

⚙The process of "Flash Drying" involves the controlled introduction of wet product into a high-velocity, high-temperature stream of gas in which the moisture is “flashed” off or quickly driven out of the material being dehydrated. While the process may seem simple in theory, Midwest Custom Solutions is here to ensure it also works for you in application.

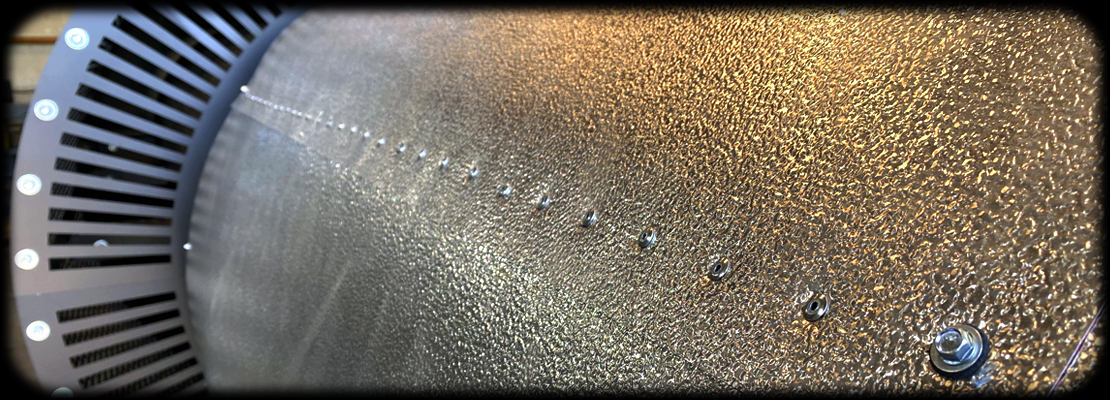

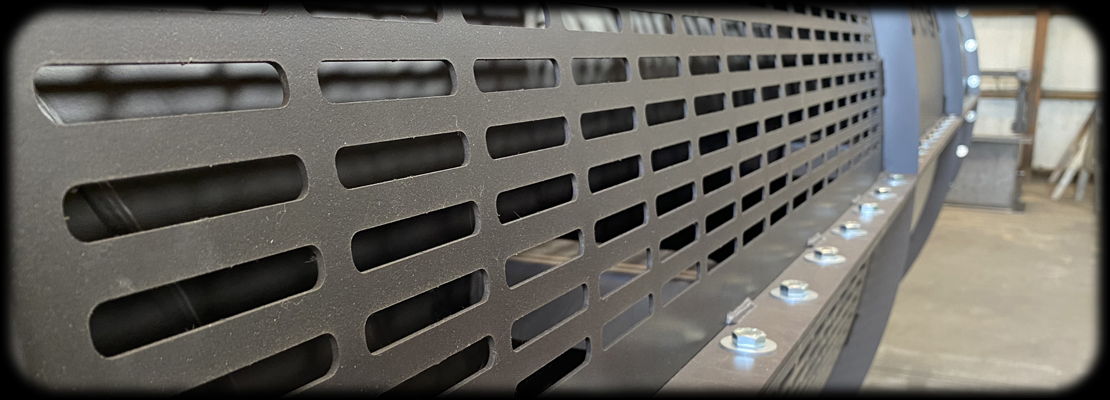

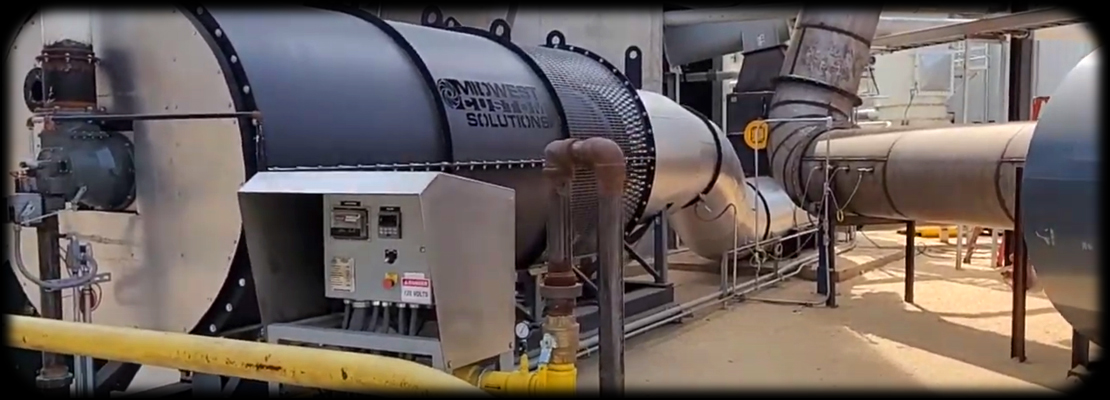

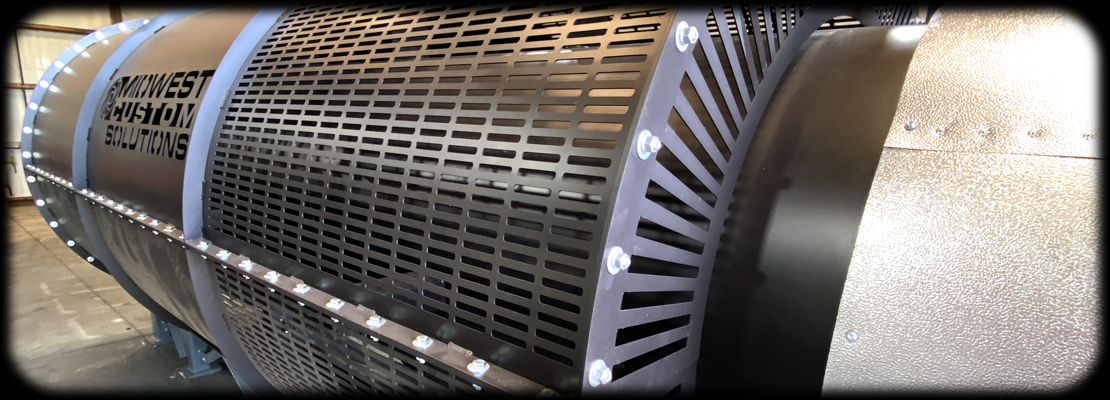

⚙Knowing and understanding the rigorous operational conditions and strenuous processing environments that Industrial Flash Drying imposes on the processing equipment involved, Midwest Custom Solutions has engineered durability, strength and longevity into the XFD-48 design, and our artisan manufacturing technicians build hardwearing durability into every aspect of your new drying system.

⚙The aft bulkhead and burner mount have been structurally reinforced to withstand the unseen forces of thermal cycling, and the entire dryer assembly is mounted on a muscle-bound piece of structural artwork to ensure your product investment is resolutely protected. All stress-points and thermal concerns have been arduously hardened against the harsh material processing demands of your unique dehydrating operations.

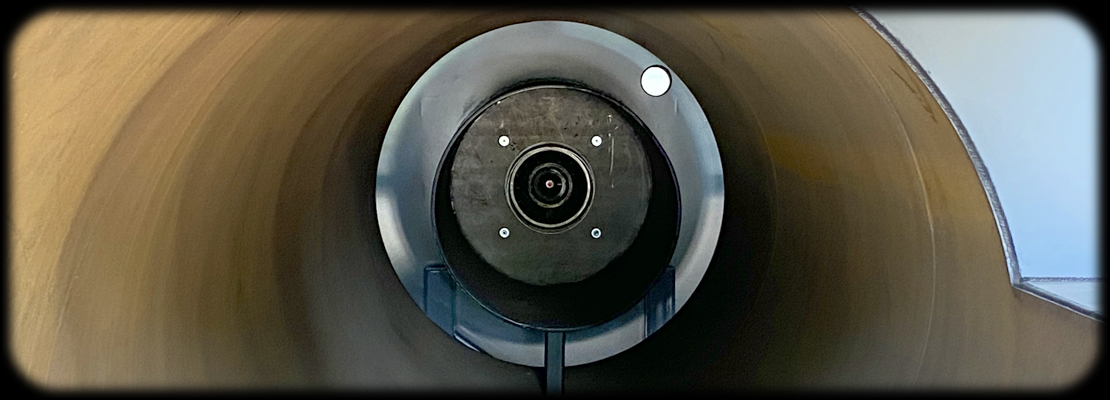

⚙Burner assemblies for our XFD Series Dryers are selected for their high-efficiency operation and extreme durability providing countless hours of safe, worry-free service in your processing operations. Burner Assemblies are selected only from industry-leading suppliers since MCS will never compromise on sub-system installations.

⚙We’ve strategically incorporated lifting lugs and pick-points into the XFD Series design for easy, quick and worry free movement and lifting - something few consider until several thousand pounds of steel are hanging in the air from the boom of a crane.

⚙Hot Surfaces are heat shielded and protected with high-temperature coatings while the flash dryer’s outlet is shrouded with mineral-fiber insulation with an overlay of stainless steel cladding. Your operator's safety and well-being will always remain our top priority at Midwest Custom Solutions.